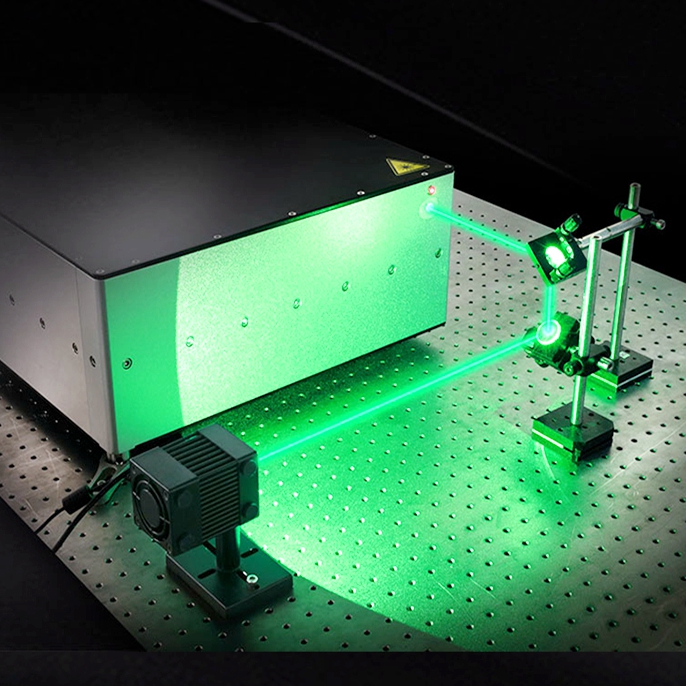

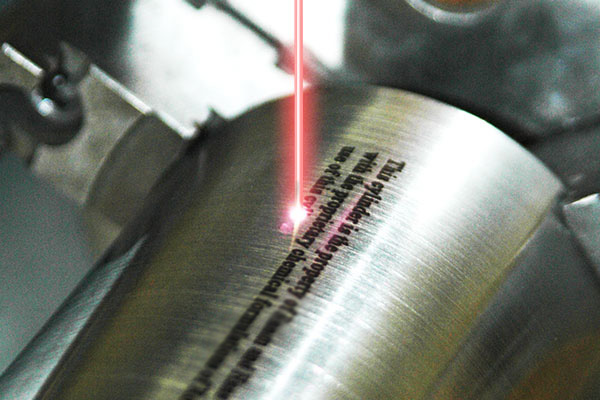

A laser is used as the heat source in the process known as laser cladding, in which a metal coating is deposited to the surface of a component using the laser. The procedure is typically utilized to generate a protective coating for the purpose of enhancing functioning and to repair surfaces that have been damaged or worn.

The process of laser cladding entails the introduction of a stream of metallic powder or wire into a melt pool that is produced by a laser beam as it scans over the surface of the target. This results in the deposition of a coating made of the desired material.

Advantages & Disadvantages

The usage of laser diode cladding, a relatively new technique, is becoming increasingly polished and applicable to current industrial settings. Despite the fact that there are still a great many drawbacks associated with the technology. In the following paragraphs, we will discuss both the benefits and the drawbacks of utilizing this method.

Advantages;

Cladding may be positioned exactly how one would like it to be.

Both the substance being deposited and the medium that it is put upon might come from a very broad variety of sources.

Deposits are completely welded to the substrate and have very little to no porosity in the process.

The heat input is kept to a minimum, which results in a narrow HAZ (heat affected zone).

When only a little amount of heat is applied, the substrate experiences only a slight amount of deformation, and there is less of a need for extra machining.

Simple to automate and incorporate into production systems with CAD/CAM and CNC machines.

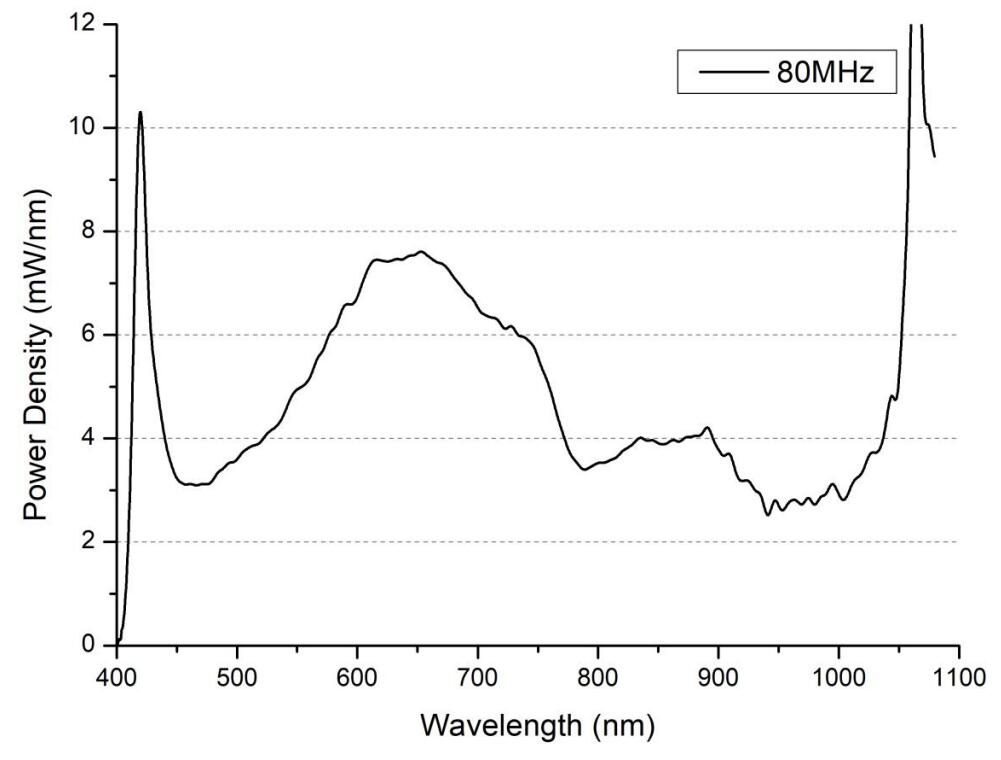

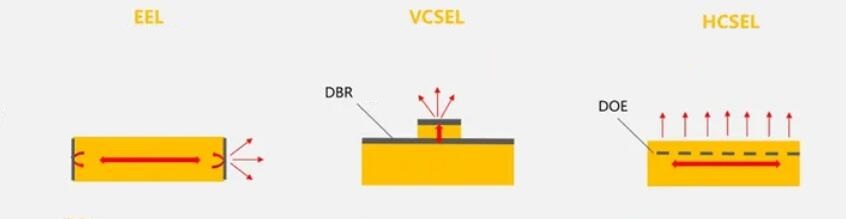

When compared to NdYAG and CO2 lasers, the features include a superior surface quality, better beam absorption, better morphological characteristics, more uniform and reproducible outcomes, and fewer fractures.

Time savings in manufacturing compared to more conventional cladding methods

Improved regulation of the temperature

A very efficient and cost-effective method of repairing components

Manufacturing of a component that is functionally graded

One of the most notable benefits of these lasers is that they have significantly lower costs of operation and maintenance.

Self-regulating systems are able to adjust for the uneven motion that might occur when they are operated manually.

In addition to providing a precise and functional coating, laser cladding allows for the rapid restoration of surfaces.

bonding in metalworking that occurs after solidification

Extremely high precision

Almost completely devoid of pore space

Consolidation in a single stage, applicable to both powder and wire

aditive fabrication of the surface cladding

5D and 3D material build-up with a lateral resolution of 30 m to 1 mm; the size of the item is not often a limiting factor.

omni-directional motions

The lifespan of the array is estimated to be at least 20,000 hours.

When overlapping passes are used, they work well together to generate a flat surface profile that only needs a little amount of post-machining work.

Can enhance the wear resistance of components by introducing a new material to the wear face.

Extremely low energy use in comparison to more conventional practices

Disadvantages;

Costs of equipment and installation that are very expensive to put up.

Large equipment size limitations. That the system cannot be moved from place to place

A rapid rate of construction might cause cracking.

The cladding may develop stress cracks if the power and setup are not done correctly.

Due to the fact that laser diodes are a relatively new technology, there is a significant lack of both availability and capabilities.