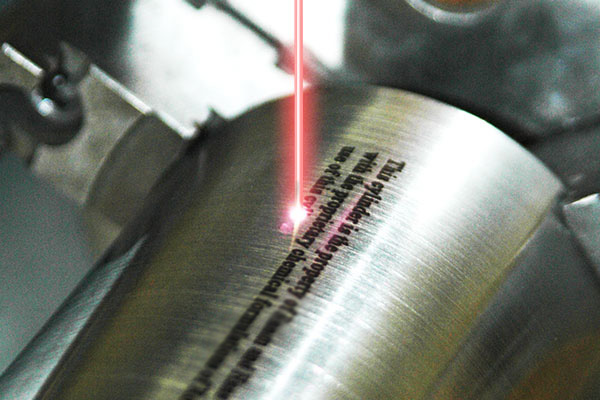

If you need “Laser Marking near me”, you may just need laser marking service nearby. Here we list the address of different laser marking service companies.

Blog

-

Where to find Laser Marking Services

We list some companies who can offer Laser Marking Services.

- lasermarkingsvs

12675 Danielson Court, Ste. 402

Poway, CA, 92064

P: 858-748-3468

E: info@lasermarkingsvs.com

Their laser marking systems are capable of marking a wide range of materials. As a guide, we have listed a number of materials below; however, please be aware that this is not an exhaustive list so please contact us if your material is not listed:

• Stainless Steel

• Wood

• Aluminum

• Carbide

• Nickel

• Titanium

• Cast Iron

• Chrome

• Painted Metal Alloys

• Multi-Coated Metals

• Plastics

• Backlit Buttons

• Polycarbonate

• Polypropylene

• PVC

• Rubber

• Composite - lasermarkingsvs

-

Laser Marking Services

You can find some Laser Marking Services online. Here are some useful advice for you to choose Laser Marking Services.

-

Davi Laser

Davi laser is a famous supplier for laser source, CO2 tube. Davi laser is a laser manufacturer in China.

You can find many resellers for davi laser on Aliexpress, such as FireRay Store , wavetopsign Official Store. Some of the resellers are in Alibaba,

-

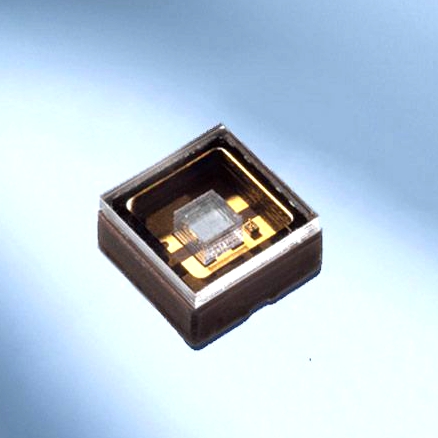

Nichia LED NCSU434A UVC 17mW 280nm 0.5W

Nichia LED NCSU434A UVC 17mW 280nm 0.5W Japan Original

High performance UV-C NCSU434A SMD LED with 280nm and 17.5mW typical radiant power

Typical voltage 5.3V, current 100mA

Typical power consumption: 0.5W

120 deg viewing angle

Dimensions (LxWxH): 3.5×3.5×1.72mmApplication areas: Disinfection, Sterilization

Weight (g) 1.000000

LED Installation Package Emitter

Color UVC Ultraviolet

Viewing Angle 120°

Forward Current Typ 350ma

Forward Voltage Typ (V) 5.3

Power (W) 0.5

Wavelength (nm) 280

Manufacturer Product Code NCSU434A UV-C

-

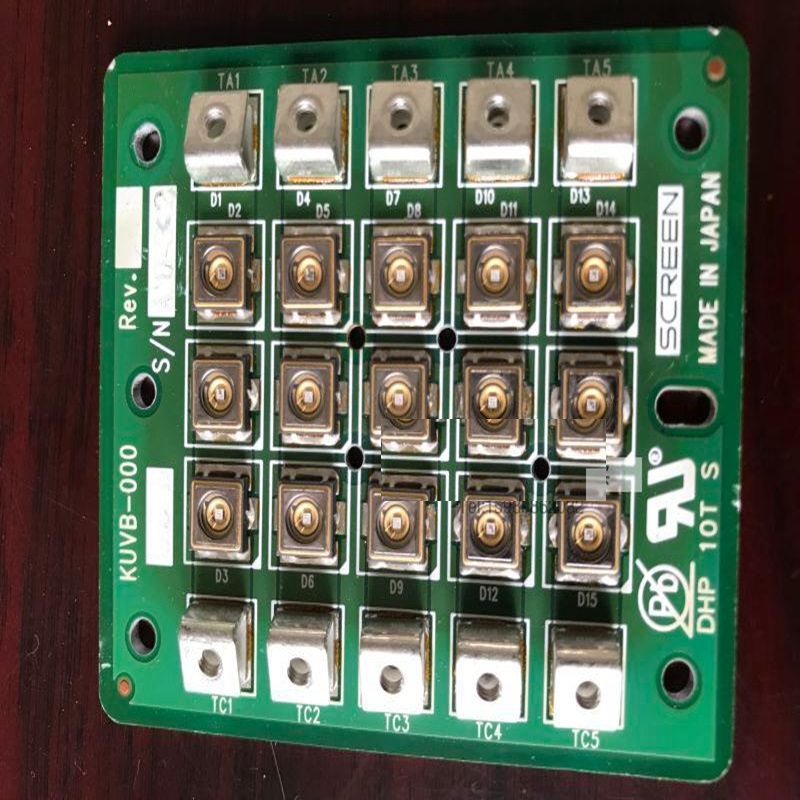

NVSU035B 395nm UV 3D printer UV module light source

3D UV LED printer curing light source module NVSU035B 395nm UV

Specification

Wavelength: 395nm

Voltage: 3.8-4V

Current: 700mA (single chip)

Power: 45W

Module size: 7553mm Luminous surface size: 5340mm -

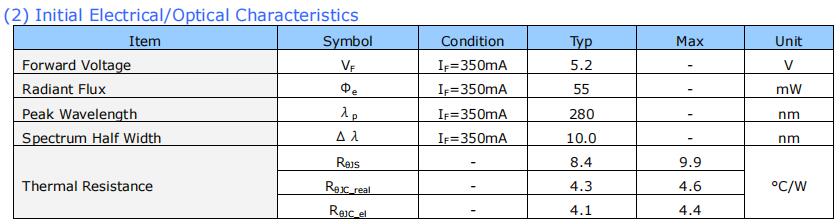

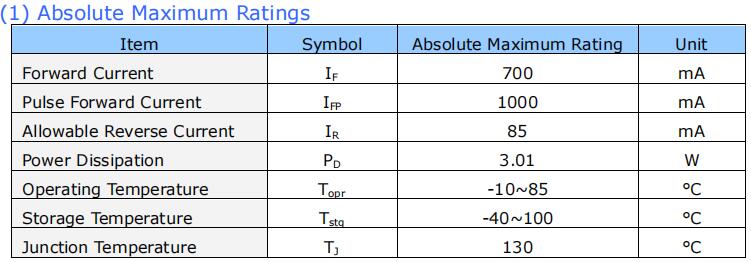

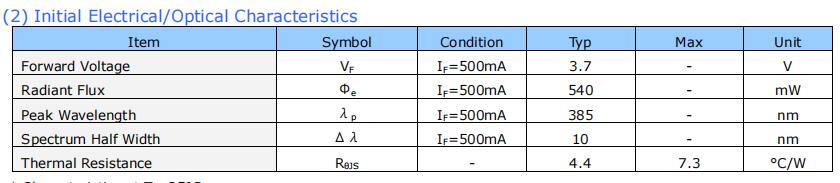

NCSU034B Nichia UV LED 385nm 540 mW

NCSU034B Nichia UV LED 385nm 540 mW

Mounting Type

Emitting Color 385 nm

Chip Material

Luminous Intensity 540 mW

Viewing Angle 120

Lens Type-Color

Forward Voltage 3.7 V

Forward Current 500 mA

Maximum Forward Voltage 4.3 V

Maximum Forward Current 1000 mA

Min-Max Operating Temperature -10C to +85C

Factory Pack 500 PCS/ReelThis LED is designed to be reflow soldered on to a PCB. If dip soldered or hand soldered,

Nichia cannot guarantee its reliability.- Reflow soldering must not be performed more than twice.

- Avoid rapid cooling. Ramp down the temperature gradually from the peak temperature.

- Nitrogen reflow soldering is recommended. Air flow soldering conditions can cause optical degradation,

caused by heat and/or atmosphere. - Repairing should not be done after the LEDs have been soldered.

It should be confirmed beforehand whether the characteristics of the LEDs will or will not be damaged by repairing. - The Die Heat Sink should be soldered to customer PCB.

If it is difficult or impossible, use high heat-dissipating adhesive. - When soldering, do not apply stress to the LED while the LED is hot.

- When using a pick and place machine, choose an appropriate nozzle for this product.

- The recommended soldering pad pattern is designed for attachment of the LED without problems.

When precise mounting accuracy is required, such as high-density mounting, ensure that the size and shape of the pad

are suitable for the circuit design. - When flux is used, it should be a halogen free flux. Ensure that the manufacturing process is not designed in a manner

where the flux will come in contact with the LEDs. - Make sure that there are no issues with the type and amount of solder that is being used.

-

Beauty Lab and Laser

Beauty Lab and Laser

beauty lab laser

-

KSS-213C Optical Laser Lens Sellers

Download the datasheet for KSS-213C Optical Laser Lens here:

USA:

Laserse Inc. KSS-213C Optical Laser Lens Pickup Replacement Parts .