NCSU034B Nichia UV LED 385nm 540 mW

Mounting Type

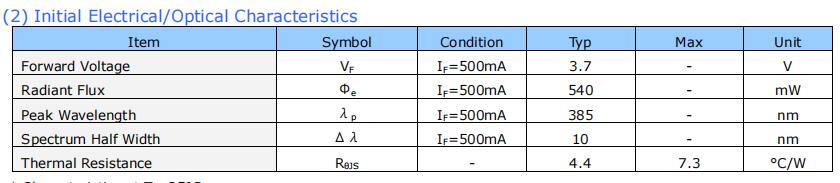

Emitting Color 385 nm

Chip Material

Luminous Intensity 540 mW

Viewing Angle 120

Lens Type-Color

Forward Voltage 3.7 V

Forward Current 500 mA

Maximum Forward Voltage 4.3 V

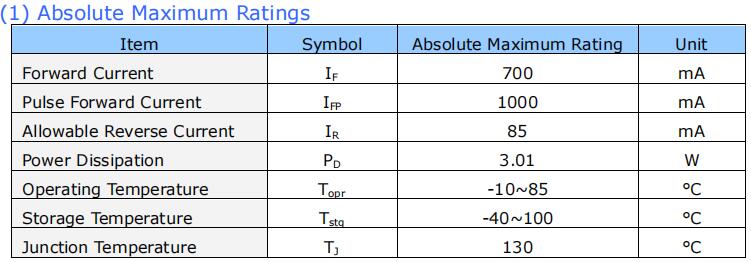

Maximum Forward Current 1000 mA

Min-Max Operating Temperature -10C to +85C

Factory Pack 500 PCS/Reel

This LED is designed to be reflow soldered on to a PCB. If dip soldered or hand soldered,

Nichia cannot guarantee its reliability.

- Reflow soldering must not be performed more than twice.

- Avoid rapid cooling. Ramp down the temperature gradually from the peak temperature.

- Nitrogen reflow soldering is recommended. Air flow soldering conditions can cause optical degradation,

caused by heat and/or atmosphere. - Repairing should not be done after the LEDs have been soldered.

It should be confirmed beforehand whether the characteristics of the LEDs will or will not be damaged by repairing. - The Die Heat Sink should be soldered to customer PCB.

If it is difficult or impossible, use high heat-dissipating adhesive. - When soldering, do not apply stress to the LED while the LED is hot.

- When using a pick and place machine, choose an appropriate nozzle for this product.

- The recommended soldering pad pattern is designed for attachment of the LED without problems.

When precise mounting accuracy is required, such as high-density mounting, ensure that the size and shape of the pad

are suitable for the circuit design. - When flux is used, it should be a halogen free flux. Ensure that the manufacturing process is not designed in a manner

where the flux will come in contact with the LEDs. - Make sure that there are no issues with the type and amount of solder that is being used.