IPG has two types Thulium Fiber Laser:

TLM and TLR, 1-100 W

TLM and TLR,100-500 W

IPG has two types Thulium Fiber Laser:

TLM and TLR, 1-100 W

TLM and TLR,100-500 W

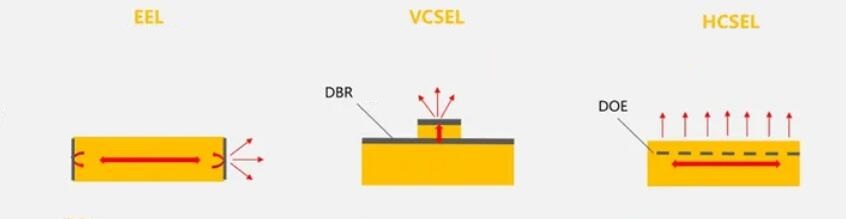

Comparison between HCSEL, VCSEL and EEL

Different from LED light sources, HCSEL laser are horizontal resonance and vertical light-emitting surface of the cavity. It has the advantages of VCSEL in overall tape-out and easy packaging at the wafer level. HCSEL laser has the long cavity length and high power of EEL.

Compared with VCSEL:

1 . HSCEL has better beam quality, better polarization and higher signal-to-noise ratio than VCSEL.

Comparison with EEL:

laser treatment for knee replacement scar tissue. Scar tissue from a knee replacement can be treated using lasers.

The use of laser treatment helps to lessen the production of scar tissue, which in turn lowers inflammation levels and expands a patient’s range of motion. This leads in a quicker recovery as well as the possibility to begin physical treatment sooner or to increase the efficiency of physical treatment that is already being received.

Treatment Options for Knee Scar Tissue

Treatment options for arthrofibrosis are dependent on the amount of scar tissue that has grown in the affected knee. In many instances, a rigorous course of physical treatment might resolve the issue once and for all. People who have conditions that are more severe can require further surgical procedures. Take a look at the many kinds of treatment that could be provided to you.

Treatment with physical treatment involves the use of exercises designed by a physical therapist to help strengthen the tissues and muscles surrounding your knee joint. This covers various kinds of passive stretching as well as approaches that include physical mobilization.

During the manipulation process, the joint will be moved in very particular ways in order to loosen and break up the scar tissue. This is often done under the influence of anesthetic.

Arthroscopic Procedure: Sometimes, your physician will offer arthrolysis, a minimally invasive operation to eliminate scar tissue. This surgery can be done in conjunction with arthroscopic surgery. This kind of treatment is gaining increasing levels of acceptance.

Open Knee Surgery: If your arthrofibrosis is severe, you may require extra surgery in addition to the open knee surgery. Your doctor will most likely recommend continuing your physical treatment in some kind.

It is imperative that you get treatment as soon as possible if you have just undergone knee surgery or have a persistent injury in order to keep the full range of motion in your knee.

After having knee replacement surgery, what is the best way to break up the scar tissue?

Scar tissue can be broken up with this treatment.

treatment of the Physical Kind Scar tissue surrounding a joint can be broken up with the use of physical treatment, which can be helpful…

Treatment Using Lasers…

Injections of Corticosteroids…

Shockwave treatment is used to disrupt the scar tissue….

Scar tissue can be removed using surgical procedures.

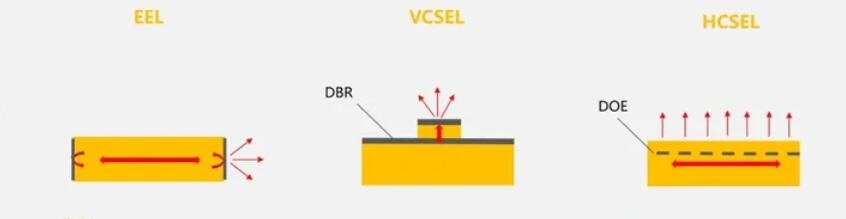

trimble x7

The Trimble X7 is a high-speed 3D laser scanner that has integrated HDR imaging, automated calibration, survey-grade self-leveling, and a laser pointer. It also combines servo motor and scanning mirror in one device. The Perspective of Trimble Software that is intuitive to use for controlling scanners, seeing 3D data, and processing it.

Powered by Trimble® Perspective, this high-speed 3D laser scanning system combines innovative technologies with the goal of simplifying adoption, increasing efficiency, and providing trust in the field.

Automatic Calibration: Have full trust in every scan with the first intelligent calibration system available in the industry. There are neither aims nor requirements for user engagement. reports of calibration that are generated on demand

Automatic survey grade level adjustment referred to as self-leveling.

Your field productivity may be increased with the industry’s most complete automatic registration solution, which is offered by Trimble Registration Assist.

The Laser Pointer is used to provide visual confirmation of particular points that are to be measured by Trimble Perspective.

In Trimble Perspective, georeferencing is accomplished by linking registered scans to a project coordinate system.

Where can I find out about the Trimble X7’s range?

0.6m – 80m

Range: 0.6m – 80m. Accuracy of the range is 2 mm. The range principle is a high-speed, digital method of measuring the time-of-flight distance.

The Trimble® TSC7 controller is a powerful all-in-one device that combines the capabilities of a tablet, laptop, and survey-rugged field controller. When used in conjunction with the Trimble AccessTM field software, the TSC7 provides the most recent advancements in field technology as well as optimized processes and makes it possible to survey in the field in powerful new ways.

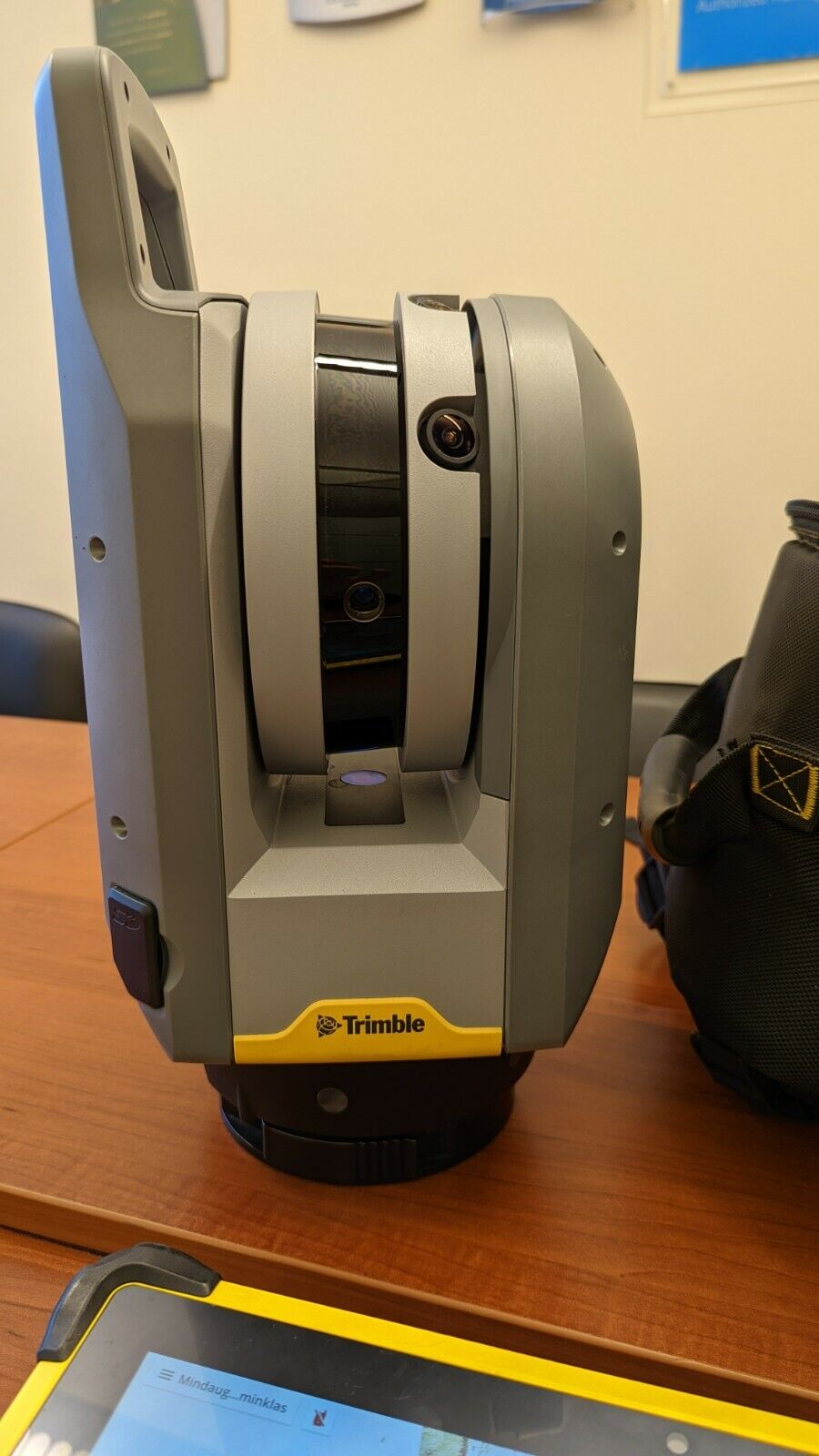

A laser is used as the heat source in the process known as laser cladding, in which a metal coating is deposited to the surface of a component using the laser. The procedure is typically utilized to generate a protective coating for the purpose of enhancing functioning and to repair surfaces that have been damaged or worn.

The process of laser cladding entails the introduction of a stream of metallic powder or wire into a melt pool that is produced by a laser beam as it scans over the surface of the target. This results in the deposition of a coating made of the desired material.

Advantages & Disadvantages

The usage of laser diode cladding, a relatively new technique, is becoming increasingly polished and applicable to current industrial settings. Despite the fact that there are still a great many drawbacks associated with the technology. In the following paragraphs, we will discuss both the benefits and the drawbacks of utilizing this method.

Advantages;

Cladding may be positioned exactly how one would like it to be.

Both the substance being deposited and the medium that it is put upon might come from a very broad variety of sources.

Deposits are completely welded to the substrate and have very little to no porosity in the process.

The heat input is kept to a minimum, which results in a narrow HAZ (heat affected zone).

When only a little amount of heat is applied, the substrate experiences only a slight amount of deformation, and there is less of a need for extra machining.

Simple to automate and incorporate into production systems with CAD/CAM and CNC machines.

When compared to NdYAG and CO2 lasers, the features include a superior surface quality, better beam absorption, better morphological characteristics, more uniform and reproducible outcomes, and fewer fractures.

Time savings in manufacturing compared to more conventional cladding methods

Improved regulation of the temperature

A very efficient and cost-effective method of repairing components

Manufacturing of a component that is functionally graded

One of the most notable benefits of these lasers is that they have significantly lower costs of operation and maintenance.

Self-regulating systems are able to adjust for the uneven motion that might occur when they are operated manually.

In addition to providing a precise and functional coating, laser cladding allows for the rapid restoration of surfaces.

bonding in metalworking that occurs after solidification

Extremely high precision

Almost completely devoid of pore space

Consolidation in a single stage, applicable to both powder and wire

aditive fabrication of the surface cladding

5D and 3D material build-up with a lateral resolution of 30 m to 1 mm; the size of the item is not often a limiting factor.

omni-directional motions

The lifespan of the array is estimated to be at least 20,000 hours.

When overlapping passes are used, they work well together to generate a flat surface profile that only needs a little amount of post-machining work.

Can enhance the wear resistance of components by introducing a new material to the wear face.

Extremely low energy use in comparison to more conventional practices

Disadvantages;

Costs of equipment and installation that are very expensive to put up.

Large equipment size limitations. That the system cannot be moved from place to place

A rapid rate of construction might cause cracking.

The cladding may develop stress cracks if the power and setup are not done correctly.

Due to the fact that laser diodes are a relatively new technology, there is a significant lack of both availability and capabilities.

Instead of using a liquid or gas as in dye or gas lasers, a solid-state laser uses a solid as its gain medium.

Instead of using a liquid or gas as in dye or gas lasers, a solid-state laser uses a solid as its gain medium. Semiconductor lasers are also solid-state devices, however they are typically classified separately from traditional laser diodes.

Metal cutting, medical procedures including eye surgery, laser printer and projector RGB light sources, environmental instrumentation measures, optical transmission systems, and even nuclear fusion are just some of the many uses for solid-state lasers.

The divergence of solid-state lasers varies widely, from 1 milliradian to 20 milliradians, which is a major drawback of these devices. Similarly to CO2 lasers, the output power is relatively low. Loss of power happens when the rod gets too hot, as is the case with solid-state lasers due to thermal lasing.

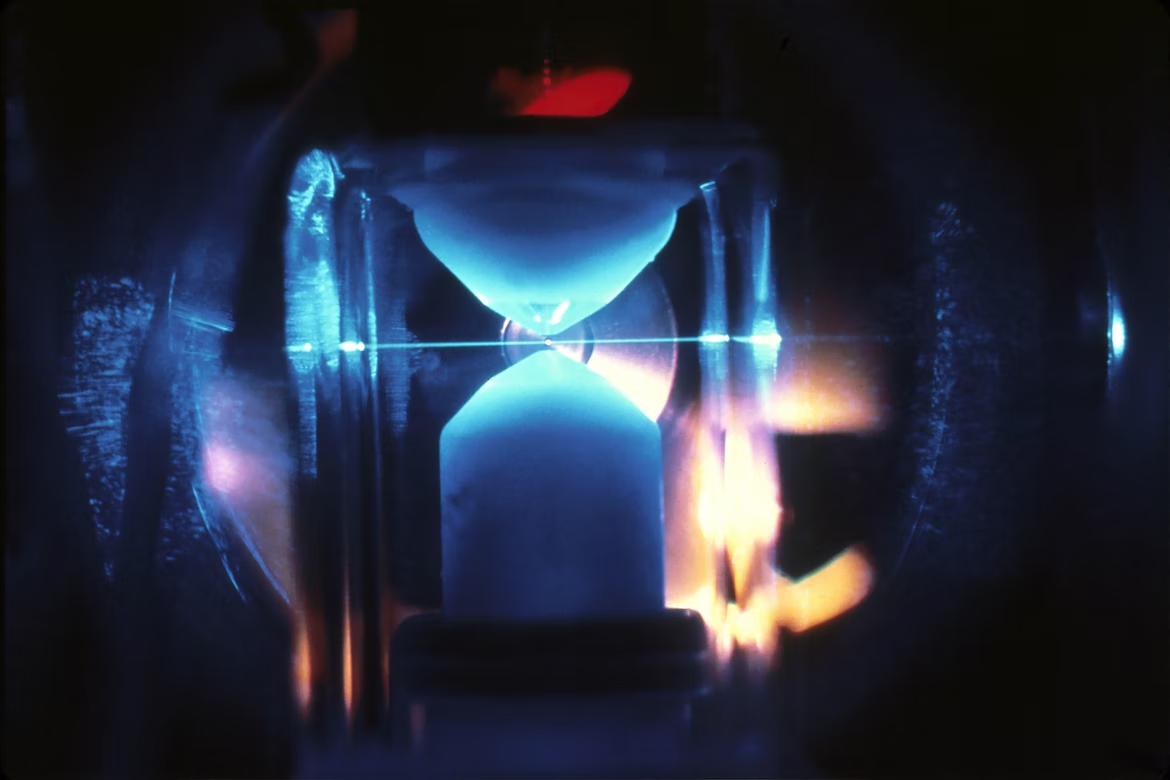

Excimer lasers, also known as exciplex lasers, are a type of ultraviolet laser that are commonly used in the production of microelectronic devices, semiconductor-based integrated circuits or “chips,” eye surgery, and micromachining. Excimer lasers have been widely used in high-resolution photolithography machines since the 1960s, and are one of the critical technologies required for microelectronic chip manufacturing.

An excimer laser typically employs a noble gas (argon, krypton, or xenon) in conjunction with a reactive gas (fluorine or chlorine). Under the right conditions of electrical stimulation and high pressure, a pseudo-molecule known as an excimer (or, in the case of noble gas halides, exciplex) is formed, which can only exist in an energized state and can generate ultraviolet laser light.

Because an excimer molecule has a bound (associative) excited state but a repulsive (dissociative) ground state, laser action occurs. Noble gases, such as xenon and krypton, are extremely inert and rarely form chemical compounds. When excited (by electrical discharge or high-energy electron beams), they can form temporarily bound molecules with themselves (excimer) or with halogens such as fluorine and chlorine (exciplex). The excited compound can release its excess energy through spontaneous or stimulated emission, resulting in a strongly repulsive ground state molecule that dissociates back into two unbound atoms very quickly (on the order of a picosecond). This results in a population inversion.

An excimer laser’s wavelength is determined by the molecules used and is typically in the ultraviolet range of electromagnetic radiation:

Relative Excimer Wavelength Power

Ar2* 126 nm

Kr2* 146 nm

F2* 157 nm

Xe2* 172 & 175 nm

ArF 193 nm 60

222 nm 25 KrCl

KrF 248 nm 100

XeBr 282nm

308 nm XeCl 50

XeF 351 nm 45

Excimer lasers are light pulse-emitting gas lasers that produce an excited dimer via an electric discharge of a gas mixture containing an inert gas and a halogen gas, resulting in a molecule ArF that exists only in the excited state and has a life time of the order of 20ns.

Excimer Laser Therapy is a laser beam that uses ultraviolet B (UVB) light to treat the affected areas of skin.Any area of the body can be treated, including the scalp.

This treatment is highly effective, safe and painless. The excimer laser treats only the affected areas of skin as opposed to a Phototherapy unit which treats all exposed skin. Treatment time is typically less than 10-15 minutes.

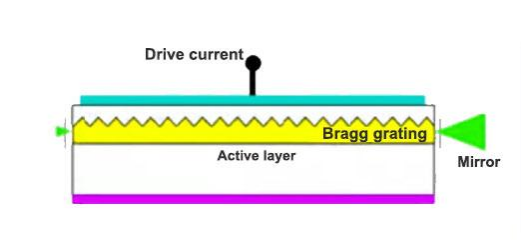

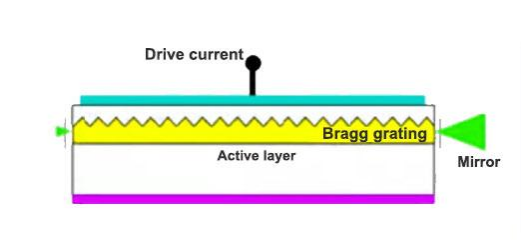

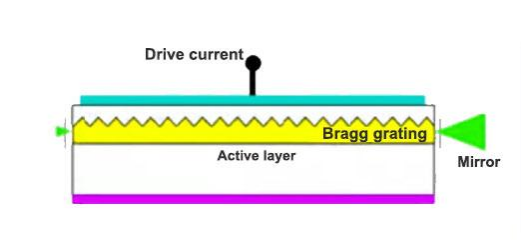

Distributed Feedback Laser

Distributed feedback laser (DFB) is a type of laser device that utilizes a diffraction grating to create an active region in a device, enabling it to emit light with a narrow line width. DFB lasers have become increasingly popular in industries and research laboratories due to their wide range of applications, such as optical communications, sensing, and medical technology.

Compared to other types of lasers, such as quantum-cascade or optical-fiber lasers, DFB lasers have unique advantages. For example, they offer stable output over time and temperature, low power consumption, and greater tolerance for misalignment in the optical system. Additionally, DFB lasers can produce light with reduced spectral line widths compared to alternative laser sources.

https://www.instagram.com/lasersonly

https://www.instagram.com/fiberopticsclub/?hl=en

The main applications for DFB lasers:

Distributed feedback laser devices use a diffraction grating for their active region, making them ideal for different scientific and industrial tasks. Their unique properties and design features enhance accuracy and performance compared to standard laser technologies.

One primary application of DFB lasers is in optical communications, which can be used in high-speed systems such as fiber-optic cables. The narrow spectral line widths enabled by the diffraction grating allow greater flexibility, allowing multiple signals to be coded onto one carrier or wavelength. As a result, these DFB fiber laser systems are increasingly reliable and robust, with less power consumption than traditional lasers.

DFB laser diodes can also be found at the heart of sensing systems, such as those used in astronomy, optical imaging, or chemical detection. The ability to produce light with high-resolution line widths enables accurate monitoring and tracking of various aspects of the environment around us, increasing safety and efficiency in many sectors.

The most significant advantages of DFB laser diode systems include the following:

Top Manufacturers of DFB lasers:

Eblana Photonics LTD: Dublin, Ireland. They specialize in MIR and NIR laser diodes. They have been in business since 2001 and have years of experience with DFB laser diodes.

CSRAyzer Optical Technology: Wuhan, China, They are an optical device supplier to a worldwide audience. They have been in business since 2013 and have one of the world’s most extensive production facilities for DFB lasers.

Frankfurt Laser Company: Friedrichsdorf, Germany. The team here has experience with DFB DBR and FP laser diodes. They offer a massive selection of power ranges and have been in business since 1994.

Conclusions:

Overall, distributed feedback laser diodes are powerful tools for scientists in many fields due to their unique properties, enabling better accuracy and performance than some standard laser technologies. As research continues into developing DFB devices, further advancements will likely lead to even broader capabilities for this type of laser diode.

Everyone’s heard about lasers, with most of us aware of the important role they play in communications. With fiber optic cabling now the best way to transmit information, lasers are more essential than ever.

Download the PDF version of this article.

A pivotal technology here is distributed feedback lasers. These are now essential to telecommunications, as well as a host of other research and commercial applications.

But what are DFB lasers?

Below, we’ll answer this question by taking at how distributed feedback diodes work, what they’re used for, and who supplies them. Whether you’re visiting out of curiosity or looking to use DFB lasers, keep reading to find out more.

DFB stands for “Distributed FeedBack laser” and refers to a type of laser used in fiber optics, telecoms, spectroscopy, atomic analysis, and precise measurement tools.

They are a type of semiconductor, quantum cascade, or optical laser that spreads light in a specific way to form a single-frequency signal.

They are valued for having low noise, a tunable wavelength, and for producing an extremely stable signal that works on a single longitudinal mode. Distributed feedback lasers are also considered extremely cost-effective despite costing more than traditional lasers.

The structure of distributed feedback laser diodes consists of an active layer with a periodic grating on top.

Unlike other types of laser structures (such as Fabry-Perot), DFB fiber laser diodes don’t have mirrors sitting on either end of an optical cavity.

Instead, DFB lasers use periodic grating to create a Bragg diffraction effect capable of producing wavelength forms from 640nm all the way up to 14,000nm.

This corrugated grating surface can produce changes in the refractive index of the signal, acting as a wavelength-selecting element alongside a mirror.

This is then reflected back into the diode’s internal cavity, transforming it into a resonator.

This alternative approach to diode structure produces a DFB laser linewidth that is narrow with a waveform that doesn’t mode hop.

Properly implemented, this distributed feedback suppresses non-single modes near the Bragg wavelength. This produces strong and clear signals that can operate over tens of miles before coherence becomes an issue.

This means fast modulation speeds of up to 15Gbps and DFB lasers being less susceptible to temperature interference than other types of laser.

Distributed feedback lasers typically come in two varieties:

Also known as semiconductor DFB lasers, diode DFBs are built with an internal periodic grating structure on top of the active region or laterally coupled on both sides.

These diodes use the internal grating structure as a waveguide and have a linewidth value of 200 MHz and higher.

There are also fiber lasers that use Bragg grating to distribute and amplify light reflection through a fiber optic cable. DFB fiber lasers have limited output power but are compact and efficient.

This is considered a more difficult approach than semiconductor DFBs, however, as integrating high-contrast periodic grating into the cable is challenging.

Because the wavelength of DFB lasers can be finely tuned, they are highly prized within a variety of industries for a wide range of applications.

As well as barcode readers and image scanning, DFBs find themselves used most commonly for the following:

There are now manufacturers across the globe producing DFB lasers. Some of the main DFB suppliers include:

Manufacturing DFB lasers is a lot more complex than traditional Fabry-Perot-type lasers.

As it stands, DFB manufacturing has a significantly lower yield rate, with each individual unit requiring more robust testing. However, with a single-mode output that is considerably more stable, DFB lasers are highly prized and in demand despite their higher price.

DFB laser fabrication begins with a crystalline silicon structure called an epitaxial wafer. This wafer also contains rare materials that will help modulate the wavelength and power of the laser.

Using cutting-edge machines, gain regions and gratings are buried under cladding layers with special coatings applied to facilitate mode selection.

A single wafer will produce multiple DFBs once cleaved, chipped, and housed.

After fabrication, all DFBs undergo rigorous testing, including temperature resistance and and voltage checks, before being sold.

DBR lasers and DFB lasers are similar in that they both use Bragg gratings.

Structurally DBR lasers are an older technology that uses a high index contrast and high reflectivity. Manufacturing DBR lasers produce a higher yield but only produces a single frequency.

DFB lasers, however, are low index contrast with low reflectivity with a tunable wavelength.

Davi laser is a famous supplier for laser source, CO2 tube. Davi laser is a laser manufacturer in China.

You can find many resellers for davi laser on Aliexpress, such as FireRay Store , wavetopsign Official Store. Some of the resellers are in Alibaba,