Everyone’s heard about lasers, with most of us aware of the important role they play in communications. With fiber optic cabling now the best way to transmit information, lasers are more essential than ever.

Download the PDF version of this article.

A pivotal technology here is distributed feedback lasers. These are now essential to telecommunications, as well as a host of other research and commercial applications.

But what are DFB lasers?

Below, we’ll answer this question by taking at how distributed feedback diodes work, what they’re used for, and who supplies them. Whether you’re visiting out of curiosity or looking to use DFB lasers, keep reading to find out more.

What are DFB lasers?

DFB stands for “Distributed FeedBack laser” and refers to a type of laser used in fiber optics, telecoms, spectroscopy, atomic analysis, and precise measurement tools.

They are a type of semiconductor, quantum cascade, or optical laser that spreads light in a specific way to form a single-frequency signal.

They are valued for having low noise, a tunable wavelength, and for producing an extremely stable signal that works on a single longitudinal mode. Distributed feedback lasers are also considered extremely cost-effective despite costing more than traditional lasers.

DFB lasers use Bragg grating

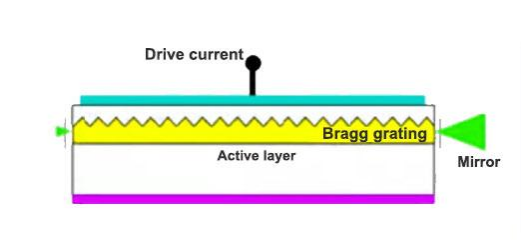

The structure of distributed feedback laser diodes consists of an active layer with a periodic grating on top.

Unlike other types of laser structures (such as Fabry-Perot), DFB fiber laser diodes don’t have mirrors sitting on either end of an optical cavity.

Instead, DFB lasers use periodic grating to create a Bragg diffraction effect capable of producing wavelength forms from 640nm all the way up to 14,000nm.

This corrugated grating surface can produce changes in the refractive index of the signal, acting as a wavelength-selecting element alongside a mirror.

This is then reflected back into the diode’s internal cavity, transforming it into a resonator.

Advantages and uses of DFB lasers

- Modulation speeds up to 15Gbps

- Narrow linewidth

- Low-noise

- Temperature resistant

- Excellent side mode suppression

- Strong signal over long distances

This alternative approach to diode structure produces a DFB laser linewidth that is narrow with a waveform that doesn’t mode hop.

Properly implemented, this distributed feedback suppresses non-single modes near the Bragg wavelength. This produces strong and clear signals that can operate over tens of miles before coherence becomes an issue.

This means fast modulation speeds of up to 15Gbps and DFB lasers being less susceptible to temperature interference than other types of laser.

Types of DFB lasers

Distributed feedback lasers typically come in two varieties:

Semiconductor DFBs

Also known as semiconductor DFB lasers, diode DFBs are built with an internal periodic grating structure on top of the active region or laterally coupled on both sides.

These diodes use the internal grating structure as a waveguide and have a linewidth value of 200 MHz and higher.

Fiber lasers

There are also fiber lasers that use Bragg grating to distribute and amplify light reflection through a fiber optic cable. DFB fiber lasers have limited output power but are compact and efficient.

This is considered a more difficult approach than semiconductor DFBs, however, as integrating high-contrast periodic grating into the cable is challenging.

Uses of DFB lasers

Because the wavelength of DFB lasers can be finely tuned, they are highly prized within a variety of industries for a wide range of applications.

As well as barcode readers and image scanning, DFBs find themselves used most commonly for the following:

- Optical communication: used by telecommunications and optical communication to carry strong, stable signals. DFB technology is especially useful for increasing the bandwidth of existing fiber networks through multiplexing.

- Spectroscopy: having a narrow linewidth and the ability to tune the wavelength make DFB lasers essential to sensing applications. DFB gas detectors, for instance, can tune laser light to match the absorption line and oscillation linewidth of a gas to detect its presence.

Click here to learn more about how DFB lasers are being used in gas sensing applications.

- Medical instruments: now that the size and cost of DFB lasers have become more commercially viable, they are increasingly being used within the medical field. Specifically, distributed feedback lasers are used to treat soft tissue issues such as cancerous tumors.

Where can I find DFB laser suppliers?

There are now manufacturers across the globe producing DFB lasers. Some of the main DFB suppliers include:

- AeroDIODE: producing single-mode laser diodes capable of 180mW output power.

- AlphaLas: distributed feedback laser diodes at wavelengths including 1030 to 1064nm.

- Frankfurt Laser Company: offering DFB laser diodes with wavelengths ranging from 760nm to 3640nm.

- iXblue: using Bragg grating to produce fiber lasers with extremely narrow linewidths with zero mode-hopping.

- RPMC Lasers: large selection of DFB and quantum cascade lasers.

- TeraXion: packaging DFB semiconductors, temperature controllers, and low-noise current sources within a single product.

- Toptica Photonics: reliable DFB lasers in wavelengths ranging from 633nm to 3500nm.

FAQs

Why are DFBs more expensive than FP lasers?

Manufacturing DFB lasers is a lot more complex than traditional Fabry-Perot-type lasers.

As it stands, DFB manufacturing has a significantly lower yield rate, with each individual unit requiring more robust testing. However, with a single-mode output that is considerably more stable, DFB lasers are highly prized and in demand despite their higher price.

How are DFB lasers made?

DFB laser fabrication begins with a crystalline silicon structure called an epitaxial wafer. This wafer also contains rare materials that will help modulate the wavelength and power of the laser.

Using cutting-edge machines, gain regions and gratings are buried under cladding layers with special coatings applied to facilitate mode selection.

A single wafer will produce multiple DFBs once cleaved, chipped, and housed.

After fabrication, all DFBs undergo rigorous testing, including temperature resistance and and voltage checks, before being sold.

What’s the difference between DFB lasers vs. DBR lasers?

DBR lasers and DFB lasers are similar in that they both use Bragg gratings.

Structurally DBR lasers are an older technology that uses a high index contrast and high reflectivity. Manufacturing DBR lasers produce a higher yield but only produces a single frequency.

DFB lasers, however, are low index contrast with low reflectivity with a tunable wavelength.