Laser Marking: CO2 vs. Fiber vs. UV Lasers

UV Lasers

UV lasers work a little differently to their CO2 or Fibre based siblings as they do not damage the materials surrounding surface, using a far lower power form of marking. This makes them the best of the bunch when it comes to “marking”, suitable for anything from fruit, to glass, teflon, diamond, silicone, plastic and precious metals. You really can mark almost anything with a UV laser!

How do UV laser marking systems work?

Operating at 355nm, UV lasers have a much shorter wavelength than the other technologies here. Using a process termed “cold processing”, UV lasers shoot high-energy photons in the ultraviolet spectrum that break the chemical bonds in the material which causes the material to undergo non-thermal process damage. This process does not produce thermal deformation (heat damage) on the inner layers and nearby areas of the target area.

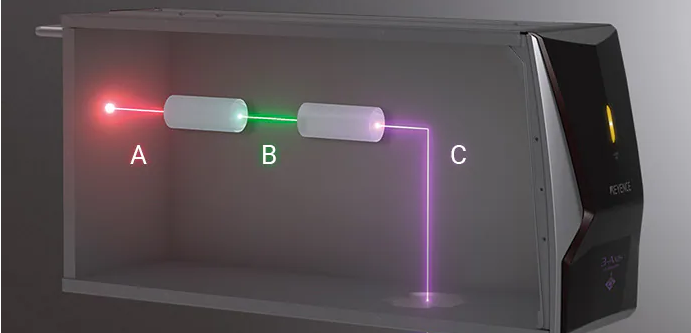

A UV laser’s wavelength is one-third of standard wavelength lasers, therefore often referred to as third-harmonic generation (THG) lasers. This wavelength is achieved by passing a standard wavelength laser at 1064 nm through a non-linear crystal, reducing it to 532 nm, this is then passed through another crystal, reducing its wavelength further, down to the working 355 nm.

In summary, the UV marking process is extremely fine and controlled, making it great for delicate or accurate work. However, due to the process this technology employs, a UV laser marking system is not normally suitable for engraving or cutting.

Pros

Suitable for marking the widest range of materials

Great for delicate, accurate work

Very low power requirements

Long-life and maintenance-free period

Cons

Not very suitable for cutting or engraving

More expensive than CO2

Fiber Laser

Fiber lasers are the go-to option for part marking, engraving and especially metal. They are very well established in many industries and are often found on manufacturing lines, workshops and more, all around the world.

With most fiber laser modules possessing more than 100,000 operating hours before any maintenance is needed, they are exceptionally reliable (however other components in a laser marking system may require regular service). Moreover, as fiber laser engraver can be easily adjusted to achieve greater depth, they are very flexible and easy-to-use.

Operating at the 1,064nm wavelength, they are very well suited to metals, but can also operate on a much wider array of materials. This is why they are the most common choice for traceability marks such as barcodes, QR codes and text. Plus, their use for other graphics on things like personalised items, switches, phones, jewellery, becomes more popular day-by-day.

How do fiber laser engravers work?

When a fibre laser meets an object it evaporates the surface material to expose deeper material, essentially “carving” by chemical and physical changes. These changes are caused by the light energy (photons) reacting in the target area.

Fibre lasers possess a high electro-optical conversion efficiency, in layman’s terms this means they convert more of the energy to light (compared to CO2). In reality, this means fibre laser systems require less power to effect a material, resulting in a low power consumption for a fibre laser marking machine.

Types of Fiber Lasers

There are two common types of fibre laser you will find offered from manufacturers, we offer both types to suit the users budget. The main difference between these types of technology is the variety of pulse width and frequency.

Q-Switched

Arguably the most commonly found type of fibre laser source, it is also the cheapest. They are typically not as efficient nor do they possess as wide a range of pulse modulations. In turn, this means they are less flexible than a MOPA laser and are much more prone to deforming different materials.

MOPA

A MOPA laser is much more flexible, with a range of pulse width and frequency adjustments available they can suit more materials and are less prone to creating unwanted deformations once setup correctly. However, MOPA laser sources are quite varied in themselves, with both quality and modulation versatility differing between manufacturers. They are also more expensive than Q-Switched systems.

Pros

Versatile range of applications

Long-life and maintenance-free period

Fast engraving speeds

Cons

More expensive than CO2 lasers

Less versatile for marking than UV

Not suitable for some organic materials (wood, glass, fabric etc.)

CO2 Lasers

CO2 laser cutters and engravers are excellent for organic materials like rubber, wood, paper, glass and ceramic. They are also the go-to choice for cutting acrylic and other plastics.

CO2 systems are amongst the most common type of laser used for industrial engraving and cutting. Smaller, low power units are those most commonly used by hobbyists due to their low cost (but also have a far lower operating lifetime).

How do they work?

Making use of CO2 gas in a sealed tube, acting as the laser medium, they operate at the 10,600nm wavelength. Unlike other technologies here, CO2 lasers typically come in a plotter format, however they are also available in a sealed unit.

FORMATS

Plotter (Plotter Laser)

A plotter system is a motion system that usually contains several stepper or servos, rails and belts. Attached to this are a series of 3 or 4 mirrors that deliver the beam via deflection to a focus carriage that usually contains a single layer plano-convex lens.

Whilst operating, the lens moves over the work area, which is usually large and rectangular in shape, to deliver the focused laser to the work piece.

Sealed (Galvo Laser)

This is a sealed unit, typically containing 2 mirrors that are attached to galvanometers. The beam is focused through a fixed lens known as an F-Theta lens that at the 1µm wavelength. The work area is constraint by the characteristics of the lens and is usually quite small and circular in shape. Technically this is known as a beam deflection laser.

TECHNOLOGIES

DC CO2 Lasers

These are the most common type of lasers found in manufacturer systems as they are relatively inexpensive. Although effective, they are slower than RF systems. Moreover, the laser power output will gradually decline and they have a shorter working lifespan (although manufacturers may quote 10,000 hours, this is only when used at low power settings).

RF CO2 Laser Systems

RF systems may be more expensive, but the benefits outway the cost. We opt for this technology in our machines so they can operate at much higher speeds, in fact, our systems are typically more than twice the speed of other manufacturers. Unlike DC, the power output of the laser will remain virtually constant over its lifespan. Moreover the quality of the beam delivery and a life expectancy can be over 20,000 hours (almost 12 years of single shift work), so it’s a “no-brainer” when looking at CO2 laser cutters.

Pros

Can mark organic materials and glass

Good engraving speeds

Lower cost (excluding galvo lasers)

Cons

Shorter lifetime

Difficulties marking metals

Less accurate than the other technologies